Industry

BAOTI Special metal co.,hasintermediate alloy ,special equipment for manufacturing etc, five divisions. Through the "safety registration license for plate heat exchanger products" and "ISO9001:2008 quality management system" certification and "D1D2 pressure vessel production license" certification.Occupational Health and Safety Management System and environmental management system" is covered by BAOTI Group Co., LTD.

Enterpriseproduct is mainly about titanium and other rare metals processing and application, with independent intellectual property rights of patented technology for eight new products. Company has formed in titanium and titanium alloy plate heat exchanger, the cathode stick, special standard equipment based of rare metal deep processing, master alloy, special aluminum alloy and titanium alloy smelting among bean, refractory metal processing and so on three big series, more than 400 kinds of specifications of the product system. Product will be applied in the chemical industry, electronics, metallurgy, petroleum, light industry, salt, and other fields.

In the aspect of metal composite material processing, rely on BAOTI Group advanced technology and equipment and strong technical force, on the basis of the original explosion composite, we use 3.3 meters wide plate rolling mill imported from German, successfully developed the explosion - rolling composite process, created a new way to domestic production of large area of thin composite plate without welding line.

"BAOTI Composite" is widely used in power plant chimney, vacuum salt, power station auxiliary machine, petrochemical industry, container manufacturing and other industries and fields.

Now it has 15000㎡standardized factory building, 5000㎡of explosion field with complete set of perfect production equipment.

Especially we use explosion – rolling process to produce thin-layer titanium/steel, duplex stainless steel/steel composite sheet. With its good quality and reputation, we become the domestic first choice to power plant chimney lining board, vacuum evaporation tank material .

In 2007, "BAOTI" metal composite board won the title of "Shaanxiprovince famous brand product".

The molybdenum wire, tungsten-aluminum alloy and tungsten-thorium alloy materials produced by BAOTI Group enjoy high reputation in the international market.

Molybdenum disc won the national gold medal;

Tungsten electrode, high temperature molybdenum products, shockproof molybdenum wire and wide molybdenum plate are at the domestic leading level.

A wide plate production line consisting of 3.3 meters reversible hot mill is introduced from Germany, which can produce titanium and titanium alloy, carbon steel, stainless steel, etc., which are 3 meters wide and 5 ~ 90 mm thick.

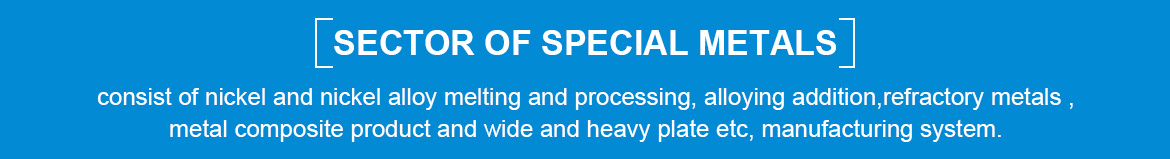

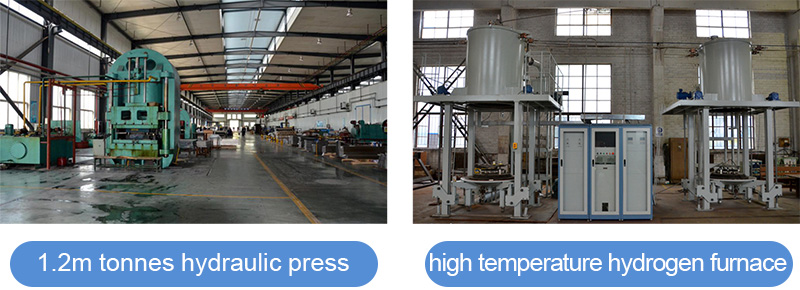

Be composed of vacuum electron bombardment furnace, vacuum arc remelting furnace, 2t vacuum induction melting furnace, 3 t vacuum electroslag furnace, 1250 t hydraulic press and 600t extruder equipment, we can produce Incoloy800, Incoloy800H, Incoloy825, Inconel600, Inconel625, Incone718, Monel - 400, MonelK - 500 specifications such as nickel and nickel alloy ingot casting, bars, forgings, pipe, plate, strip, foil and deep-processing products, capable of producing tons of nickel and its alloy products production capacity.

Products are widely used in electronics, ships, chemical industry, petrochemical, medical equipment, metallurgy, aerospace and other fields.

BAOTI Group also extend the application of titanium to daily necessities, handicrafts, medical treatment, building materials, sports, leisure, entertainment and other fields, let more and more people and industries understand titanium ,trust titanium, use titanium, making it a a symbol of fashionable and high quality life.